Whiskey Acres Distilling Co.

January 31, 2017

On a beautiful day in November we visited Whiskey Acres

The American Distilling Institute bestows the distinction upon facilities that produce spirits made from grains grown on the farm where the distillery operates.

There we met distillers Jim and Jamie Walter and Nick Nagele who showed us around the impressive farm near Dekalb, Illinois where “they cook booze”. We learned the Walter family has roots in both farming and distilling, and raising premium grains then turning them into premium spirits is their passion.The Walter family has tilled the 2,000 acres surrounding the white clapboard farmhouse since the 1930’s.

Jim Walter is an award-winning Master Farmer and contributes the wisdom he has gained over 40 years of farming.Jamie Walter inherited his mom’s talent for cooking … whiskey – he is a fifth-generation farmer and self-proclaimed “recovering attorney turned distiller”. Nick Nagele is a fifth generation farmer with a background in marketing who uses his “outside the box” thinking to push the team to grow and create unique, great tasting products.

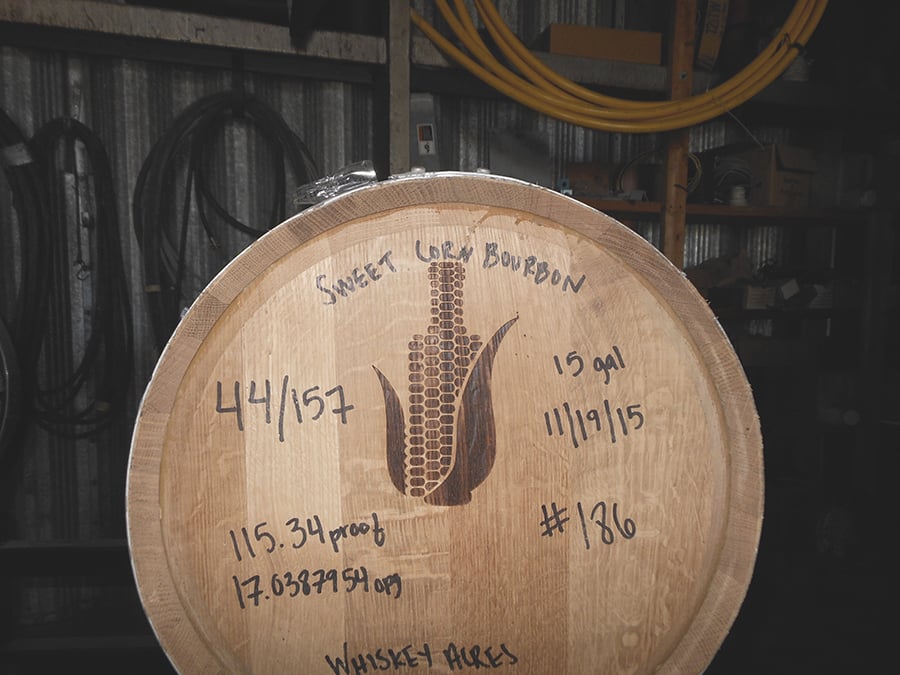

At Whiskey Acres they go well beyond small batch distilling. We learned they research and choose the best corn, wheat and rye varieties for making premium whiskey and sustainably raise them all season. At harvest, only their best grains are selected and reserved for the “Whiskey Acres Family Recipe”:

Mix water from the farm’s underground limestone aquifer with 1,000 pounds of their freshly ground grain (called mash), boil in a 500-gallon stainless steel tank for five hours then pour into tanks with live yeast and ferment for five days to create “distiller’s beer”. Then “Flo”, the 500-gallon still named after several women in the Walter family, takes over.Inside her curvaceous copper potbelly, caramel-colored beer turns into crystal-clear alcohol.

Batches are then tasted to determine quality. Nick Nagele says “The distiller’s job is much like a chef’s. We measure and mix the ingredients, monitor the cooking process to ensure the batch doesn’t burn, and taste for quality.”

Upon passing the distiller’s taste test, the alcohol is either bottled or barreled and stored for years in an outdoor galvanized steel, ribbed building shaped like a giant half-whiskey barrel until it’s ready for drinking. To read more about Whiskey Acres and what they do, click here.

Certified Farm Distillery